The owner of the Takamura R2 just sent me the link to this clip, in which he uses a grape to test the new edge:

Beiträge von kwakster

-

-

Right hand Takamura R2 Gyuto 210 mm from a local Chef, who got it as a birthday present from his wife.

The knife has already been used for two months in the commercial kitchen and it was time for it's first resharpening, which i did yesterday on a Paper Wheel with 15 micron diamond compound and then deburred on a second Paper Wheel with 0.25 micron diamond compound.

The idea was to make an edge that would do both slicing & pushcutting well, and also to remove as little steel as possible from the fine and thin R2/SG2 blade @ 63-64 HRC.

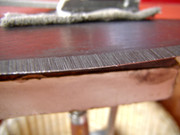

The new edge measures +/- 20 degrees inclusive and can whittle a chest hair from root-to-tip at about 4 centimeters from the point of holding, and after a few test cuts into a old piece of beechwood cutting board.I took these pics with an old Ipad and actually wanted to erase them again as being not good enough until i enlarged the last picture twice.

At first i thought i saw small dirt spots on the new bevel, but those tiny white specks were actually the sliced off peaks of the micro-dot structure on the inside of the flimsy plastic blade protector sleeve. -

Recently the second Kohetsu was returned to me for sharpening.

The knife had been used about 3 days a week quite intensively for 6 months, and was touched up from time to time by the owner on an MDF strop coated with 1.0 micron diamond paste.

When i received the knife back i could see on the edge an area of about half an inch where it reflected a bit of light, i was told probably due to some sand particles that sometimes remain in vegetables.

The rest of the edge could still easily shave clean the hair on the back of my hand on skin level. -

The Cold Steel Black Bear machete is something of a crossbreed between a short machete & a bowie knife, and imo because of the untapered fairly thick & rigid blade and the resulting overall weight this model is better suited for chopping branches and smaller trees than light brush or brambles.

These machetes are manufactured for Cold Steel by Lasher Tools in South Africa from very well hardened 1055 carbon steel that is extremely tough.

Not only are they practically indestructible, but once resharpened they will also take & hold an almost unexpected good edge.

Straight from the factory they are however completely blunt or not even apexed, and what "edge" there is is also burnt due to uncooled and sloppy machine sharpening.

It will take some time and elbow grease to put on a good convex edge that will showcase the true quality of these blades, but i have found that to be more than worth it.

The original polypropylene handle on this Black Bear was both too thick and too slick for my taste, so out came the wood rasp again.

The difference in handling & grip after the contouring with the fuzzy finish is literally night and day, and the best part is that you only need one simple handtool to do it.

Very useful piece of equipment with a good price to quality ratio for bushcraft, garden maintenance, and last but not least home defense.Mods on this one:

- Polypropylene handle contoured and "fuzzy finished"

- Factory edge slightly reprofiled & resharpened to an armhair shaving convex edge (apex now lies between 30 and 35 degrees inclusive)

- Factory swedge slightly reprofiled & resharpened to an armhair shaving convex edge (apex now lies between 35 and 40 degrees inclusive)Specs:

Overall length: 45,2 cm (17.8 inches)

Blade length: 30,8 cm (12.13 inches)

Blade thickness: 2,89 mm

Steel type: 1055 carbon steel with baked-on anti-rust coating

Handle material: polypropylene plastic

Weight 510 grams

Sheath: Cor-Ex with tip protector -

-

Based on feedback from CRK owners i would definitely say that the new heat treatment protocol is a noticeable improvement.

This Rockwell C Differential Comparitor shows the hardness change in percentages:

http://bessex.com/forum/showth…id=287&highlight=Rockwell

According to this the difference between a "pre-mid-2013" Sebenza with a 59 HRC blade and a "post-mid-2013" Sebenza with a 60 HRC blade is a 4.9 percent increase in hardness.

And if you compare a "pre-mid-2013" Sebenza with a 58 HRC blade with a "post-mid-2013" Sebenza with a 60 HRC blade then the difference would be a 9.8 percent increase in hardness.

-

Another bit of info i learned only yesterday: these machetes are made by Lasher Tools, a South African company.

-

About twice a week we like to take a hike in the forests surrounding our home town, and each time we walk between 7 and 10 kilometers. (about 4 to 6 miles)

During that time i use any of my choppers to keep the walking trails clear from overgrowth, ranging from small green branches up to small trees, most of them green, some dried.

The last few weeks i've been using the modified Kukri Machete for this job, and i've been trying out different edge finishes to get a better idea of how this influences both the performance as well as the edge retention of the 1055 steel.The first edge on this machete was finished on 400 grit wet & dry with WD40 as a lubricant, while burr removal was done on the Tormek leather wheel with some Tormek paste.

At the start of a trail this edge was armhair shaving sharp on skin level, and when we returned home it was copy paper slicing sharp.

I could keep the edge at this level of sharpness for 2 other hikes by stropping it after cleaning on a piece of MDF with some 1.0 micron diamond paste.Before the fourth hike the edge was resharpened on a Rubber Wheel coated with 230 grit diamond powder using wax as a lubricant/coolant, and deburred on a Paper Wheel with 1.0 micron diamond compound.

This provides for a noticeable finer edge (yet still a bit toothy), and at the beginning of our hike the edge was treetopping armhair, and when we returned home the edge was scrape shaving armhair.

After one more hike and using only the piece of MDF with 1.0 micron diamond compound the edge is currently still at that level of sharpness.

Maybe after the next hike i will resharpen it again to a bit finer finish and see how that does.I do know it's all a bit over the top for a simple machete, and in the end i might just settle for file sharpening, but i thought i'd share.

-

Recently i bought these 2 Cold Steel Heavy Duty machetes as modding projects.

One of them now looks a bit like a slender barong with a swedge (maybe this will be sharpened later on, don't know yet)

The contoured & resurfaced polypropylene handle has a bit of a negative angle to the blade which so far seems to work well, but i haven't chopped wood with it yet.

The convex edge measures around 30 degrees inclusive and is armhair shaving sharp. -

Just found that someone is now making lapel knives from this same titanium/ceramic hybrid:

-

We had something of a storm a few weeks ago on the Veluwe, and many forest trails are still littered with broken branches and/or blocked by fallen over small trees like these 3 birches.

The modified Kukri Machete dealt fast & easy with both the de-limbing as well as chopping up the main trunks into moveable sizes. -

This is Kukri Machete nr 2 with it's new convex edge (apex at +/- 30 degrees inclusive) and resurfaced PVC handle, currently weighing 504 grams.

Nr. 3 looks the same but it already went to a friend of mine.Kukri nr 1 with it's new convex edge (apex also remaining at +/- 30 degrees inclusive) and resurfaced handle, but with a convexed area that is a bit thinner & wider compared to nr 2 and 3.

The slope on this one starts higher up the blade, and it currently weighs 474 grams.A few more pics taken in the woods.

So far it has proven to be indestructible, even with all out chopping of many types of green woods in various thickness up to small trees with a diameter of 15-20 centimeter.

No catastrophic edge failures or even rolling, while binding in thicker woods has diminished due to the thinner convex. -

Recently i bought several Cold Steel Kukri Machetes.

I had read quite a bit about this specific model, and when i could get a very good deal i grabbed them.

I mean how could i say no to 3 brand new ones for 40,00 Euro including shipping within the Netherlands ?For me these Kukri Machetes have a useful size (they fit inside my daypack), with around 2.8 mm blade thickness they are quite rigid for a machete and certainly not flimsy or wobbly, the steel so far seems well hardened, and the handle fits my hand quite well, while the softer PVC plastic material dampens shock quite effectively.

The factory edges however are only rudimentary, coming with at best a heavily burred or at worst a not even apexed "edge", which is then simply covered in a black bake-on coating.

The backs of the blades are very rough as well, with pieces of burring that were almost sharper than the main edge, and a chequered handle surface that can create blisters with prolonged use.

However with a bit of work & a few simple tools all this can easily be solved, and then the true quality of these very useful blades will come out.First i used an F.Dick coarse double cut basterd file to completely remove the heavily burred (and most likely burned) apex.

Then i used the same file to make a rough convex shape up to the now flattened apex, followed by an Oberg smooth file to refine the surface up to a new apex, but without creating a burr.

Then i used 3 grits of wet & dry with WD40 as a lubricant on a semi-hard rubber backing to smoothen the convex shape even more, bringing the apex to a burr on 180 grit and refining it through 240 grit and 400 grit.

The burr was then taken off on the Tormek leather wheel with some PA-70 paste.

You can click 2 X on each pic for a bit more detail.One of the kukri's clamped down with it's heavily burred factory apex already filed flat, but with the coarse +/- 45 degrees factory V-bevels bevels still remaining:

Starting the new convex edge by filing away the shoulders of the factory edge, then slowly working towards the flattened "apex":

I think this was actually the first one i did, later this became my tester/user to see how thin i could reasonably take the convexing process.

Almost there btw.Number two now done with the basterd file, and starting with number three:

During sanding on respectively 180, 240, and 400 grit wet & dry SiC and WD40 as a lubricant backed with an old piece of fiber reinforced rubber conveyor belt.

The new apexes fit almost perfectly in the 30 degrees inclusive slot of the Tormek WM200 Angle Master.Removing the chequered handle surface with a coarse wood rasp to give it a much more "handpalm-friendly" finish.

Right after the wood rasp treatment on the right, and one that has already seen several days of use on the left.

-

-

And it's a very valid argument i can tell you.

That is also why my Wheels have a coating of cooling wax or oil on top of the abrasive so overheating will not happen.

Something i know for sure as i test every edge i sharpen this way afterwards by cutting several times into a testing block and measuring sharpness before & after testing. -

The owner of this Maxamet PM2 had given his knife a forced patina treatment, and besides coming out a bit uneven the acid had also completely eaten away the factory apex as well as the very tip of the blade.

To say that the knife was completely blunt would have been an understatement.

The request was to give the knife a new toothy edge with a lot of bite while making it as sharp as possible.

Before sharpening:

Flattened the acid damaged "apex" some more on a 3000 grit diamond plate so i could start with fresh steel, then made a new edge on a Rubber Wheel coated with ~ 230 grit diamond powder & wax, then deburred on a Paper Wheel with 1.0 micron diamond paste & oil.

The new edge is ever so slightly convex, the new apex fits almost exactly in the 30 degree inclusive slot of my Tormek WM200 Angle Master, plus it can whittle one of my chest hairs at about 5.5 centimeters from the point of holding.

(i don't own a BESS tester)

The somewhat "fuzzy" shoulders of the new edge show how deep the acid has eaten away into the sides of the blade in some area's.

After sharpening:

-

The rough finish as it currently is would probably work very well when using the Bowie Machete as a pig sticker for hunters and also for home defense, but i still have to find out how it works for (sustained) chopping purposes.

If need be some sanding linen would make a finer surface in no time.

With a measured blade thickness of 2.75 mm the knife is actually quite rigid, certainly not flimsy or wobbly. -

Probiere Ich es mal auf Deutsch, Verzeihung für die Fehler.

Hab diesen Tipp von ein befreundeter Polizist in Texas.

In seine Arbeit hat er gelegentlich zu tun mit Leute die wegen Chemikalienmisbrauch nahezu keine Schmerzen bemerken, und eine normale ASP Dienstschlagstock kann sie einfach nicht zum stoppen bewegen.

Deswegen haben er und mehrere seine Kollegen die vordere Teile ihre ASP batons ganz mit kleine Bleikugeln ausgefüllt, und zwar bis der Haltungsfeder noch gerade einpasst.

Abschliessen wird gemacht mit etwas JB Weld und fertig ist das Ding.

Ein ASP 21" (daystick) geht so von 464 Gramm nach 502 Gramm, weil ein ASP 26"(nightstick) von 555 nach 607 Gramm geht.

Und weil das Gewicht nur im Vorderteil sitzt sind Schläge damit jetzt um ein vielfalt mehr effectiv. -

A few days ago i bought a few Cold Steel Bowie Machetes from a Dutch forum member, and today i changed the plastic grip of one of them a bit more to my liking with the use of a coarse wood rasp.

The contouring makes for a much more comfortable grip when compared to the original handle shape, and snap cuts can now be done much easier and without handle shift.

The rough surface structure left by the wood rasp also offers a much more secure grip, but only prolonged use will show if it needs more smoothing.The factory edges on these South African made versions had some burring left, but that was an easy fix on the Tormek leather wheel.

The edges are slightly convex, and each apex currently fits in the 45 degrees inclusive slot of my Tormek WM200 AngleMaster.

A bit overkill i think, so some thinning will probably follow later. -

Es sieht aus als könnte mann das auch selber machen, aber trotzdem eine gute Idee:

https://www.snaggletoothmf.com/

Ein Mitglied von Bladeforums US hat mal gefragt von welches material die Snaggletooth gefertigt sind:

"The SnaggletoothMF is injection molded of Delrin. Delrin is a very strong and resilient plastic. It has a natural lubricity and is impervious to most chemicals. Bleach seems to be it achilles' heel. Plastic springs and other high demand parts are made of Delrin because of it's great properties. We use only true Delrin which is a DuPont material. The SnaggleToothMF is very tough, not like a 3D print. If you order one, and are not satisfied we will gladly refund your money. I don't think you will be disappointed. Thanks for inquiring and I hope to hear from you again."