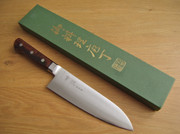

This is how i received the knife back after about a month of use in a commercial kitchen, and only after the Chef cut up several Italian artisan breads with almost rock hard crusts, which of course damaged the very hard & very thin edge.

There were both chips and rolls in the apex, but only one chip extended a hair past the polished bevels (which were starting to develop a nice blueish patina).

The undamaged parts of the apex however could still shave the hair on the back of my hand on skin level reasonably well.

(click 2 x on each pic for more detail)

The edge was restored freehand with the help of my Tormek T7 with it's SB-250 stone, refined with a Paper Wheel coated with 3.0 micron diamond compound, and deburred with a second Paper Wheel coated with 1.0 micron diamond compound, and the new apex now measures an almost exact 20 degrees inclusive.

According to the Chef this Kohetsu HAP40 is the best knife he ever owned, and from now on he will refrain from cutting those hard crusted breads with it.

He also intends to buy a nice hinoki cutting board.