These also belong in this thread:

Beiträge von kwakster

-

-

Danke für dein Beitrag Trabireiter

Möglich gibt es kein Beitragen von andere Forum Mitglieder in diesen Thread weil sie denken sie müssen für mir Englisch schreiben, aber ich kann einfaches Deutsch lesen und auch ein bisschen schreiben.

Nur wenn Ihr unter einander Deutsch schreibt wird es schnell zu schwierig, aber dann gibt es immer noch Google Translate.Wenn jemand Fragen oder Bemerkungen hat höre ich es gerne,

-

Currently busy removing the microchips from the apex with a Paper Wheel coated with 15 micron diamond compound.

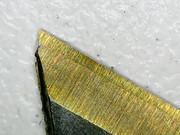

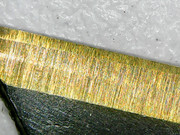

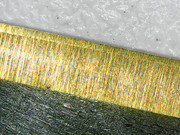

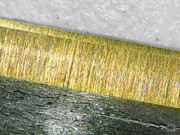

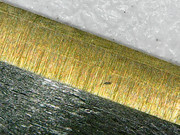

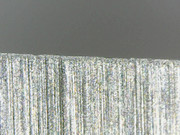

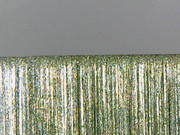

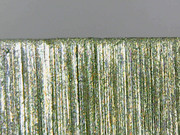

The idea is to finish the new apex with only this compound and then find out how the knife will do with the resulting rather coarse edge (for a ceramic knife)Although it remains quite difficult to capture the scratch pattern in pictures, the USB-microscope proves to be very useful in showing a sharpening fault (picture 1) and an extremely small chip remnant (picture 2).

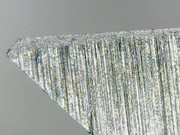

Picture 5 also shows that the apex is already becoming translucent with this finish at 25 degrees inclusive. -

Anyone have experience with Sandrin Cutlery ?

It's an Italian knife company which makes knives out of solid tungsten carbide @ 71 HRC -

-

-

-

Making reasonable pictures with an USB-Microscope takes quite a bit of practice, so that's what i'm doing at the moment.

The idea for this thread is to show some pictures of untouched factory edges from various brands, so feel free to contribute if you have some as well.

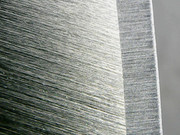

This is the first one, a factory edge with a buffed apex on a Spyderco Paramilitary 2 in CPM-S110V steel and a measured edge angle of 30 degrees inclusive: -

Spyderco aims for 30 degrees inclusive for their factory edges, but that number will vary a bit since most are done by hand on belt sanders.

In their US facility they recently started using a sharpening robot which has lead to better consistency regarding edge angles. -

The edge can now no longer cleanly cut the skin of most tomatoes, and on some types even downright sawing motions don't work anymore.

On onions i can feel that initial resistance cutting through the top layers, but on most other foods the knife continues to work well.

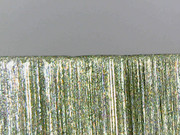

It also still scrape-shaves armhair and slices copy paper just fine, so most non-knife people would still call it quite sharp.Although focussing with my new USB-microscope is still quite the challenge i did manage to take some shots of the current edge from tip to heel, to show the edge damage in the form of microchips as well as the sharpening scratches in the bevels.

My Victorinox magnifying glass had already showed me the larger microchips, but the smaller ones and the scratches which can now be seen clearly had always remained invisible to me.

It looks like i have jumped the other diamond wheels a bit to soon before finishing with the 1 micron diamond wheel, so apparently there is some room for improvement. -

Do you have a few good pictures of the knife ?

-

That depends on how much steel from which steel type i have to remove, as factory edges can be all over the place regarding edge angle, edge finish, and visual appearance.

When only a slight regrind is needed i just use my Paper Wheel coated with 15 micron diamond compound, which is the same Wheel i also use for the edge finish on a bling & bite edge like this one.

But when more steel needs to be removed to get to the edge angle i'm after (especially high vanadium carbide steel types) i choose my Rubber Wheel with 230 grit diamond powder or even my Tormek. -

The Manix 2 lightweight in S110V is a superb knife, and it exemplifies Spyderco's motto "simplify and add lightness".

The model only seems to have two possible disadvantages: it takes up quite a bit of real estate in your pocket, and some people can't seem to get over the fact that it has an ultra lightweight plastic handle, which to them makes the knife feel cheap and not worth the asking price.

But after providing them with some links to real life tests with this knife some of them change their minds

I do hope however that the factory edges get some more attention in the future, as i already had to resharpen 5 pcs of this model that couldn't even slice copy paper.

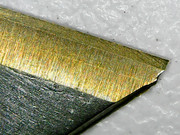

Upon inspection all these edges had visible burr remains and edge angles measured around 35 degrees inclusive.This is one of them with it's new bling & bite edge, as i call them: reprofiled to +/- 30 degrees inclusive with 230 grit diamond powder on a Rubber Wheel, refined with 15 micron diamond compound on a Paper Wheel, and deburred with 0,25 micron diamond compound on a second Paper Wheel.

To me the shiny bevels are actually a side effect, as it's the clean cutting of the large amount of vanadium carbides that i'm after. -

The knife is still being used in our kitchen in exactly the same way as described earlier, but the edge has now lost it's ability to whittle one of my chest hairs towards the root.

I tried it multiple times on 3 different hairs, but the edge did not catch any of them even once.The edge can however still shave the hair on both the back of my hand as well as on my leg on skinlevel, but i have to press the edge on my skin a bit or it will slide over the hairs without cutting them.

If i do that it will shave a patch clean.

It will also slice a piece of copy paper to confetti easily, so most non-knife people would still consider the edge to be very sharp.Through my Victorinox loupe i can now spot 5 micro-chips, which can be felt on my nail as well.

However these are not visible with my naked eyes.Will continue to use the knife to see how things develop and report back again later.

-

Tazkristi from Spyderco headquarters just posted this message on a few forums:

“Integrity is being good even if no one is watching”….

We wanted to make everyone aware we are implementing a change for 2016 that you should hear directly from us.

Spyderco will be implementing a Minimum Advertised Pricing (MAP) Policy with our retailers that will go into effect January 1, 2016.

This means that there can be no advertisements on-line or in print at a price lower than 40% off of MSRP.

We are also not raising prices on nearly all of our product line.

Our policy is slightly unconventional and is designed with everyone in mind.We are consumers too, we understand buying products based on important factors like product quality, price, business reputation, customer service, and other factors, and we understand the value of finding that great deal and knowing that you are purchasing a great product from a reliable source.

We also understand that over the last 40 years, we have cultivated unique partnerships to include consumers, retailers, wholesalers, and suppliers that have all contributed to our success in one way or another.Our number one priority is to continue to bring you Reliable High-Performance products.

We plan to continue growing our innovative product line, finding creative ways to fight counterfeit products in the marketplace and continue strengthening our relationships with those who are committed to the same goals.Many of us have our favorite store or website that we purchase from for many different reasons with price being only one of those factors.

This does not mean that on January 1st, all of our products will suddenly be extremely more expensive, instead what it means is that Spyderco is working with everyone in our network to continue bringing our products to you at fair prices through your favorite retailers.

This is a work in progress and we will continually review and apply our CQI – Constant Quality Improvement philosophy in the coming months.

The Spyderco Crew thanks you for your undeniable loyalty and continued support ! -

Does the maker have a website ?

I suppose reprofiling/sharpening/polishing an edge on such a knife wouldn't be a problem with my Paper Wheels & diamond compound, but i'm afraid that grinding a blank into a blade would be out of my league.... -

And i would like to have such a blade.

Do you think the maker has more of these blades for sale ? -

Sounds good then

If it were my knife i would probably make a handle for it out of glued leather discs, sanded to shape when dry.

Also put on a simple brass guard & pommel and it would suddenly become a very nice knife.

Think a bit like a puukko. -

Would be interested to see how the knife holds up with a 30 degrees edge angle, and also how you experience the reprofiling & sharpening process.

-

Question from a member on another knife forum:

"After all this testing would you say benefits of ceramic outweigh the attention required, compared to steel ?"

My answer:

"At this moment i wouldn't say that, as i think ceramic knives in general haven't developed as far as steel knives yet.

Most of them are still too brittle and cannot be resharpened by the end user as easily as most steel types.This particular knife however has proven itself to me already as an advancement over many other ceramic knives, as the ceramic material certainly has a much higher grindability (fact) and also seemingly a higher toughness (assumption).

While that toughness still isn't in the realm of most steel types i do notice a difference in use by much less edge chipping overall, and the chips that i see are also noticeably smaller (i need my Victorinox loupe to spot them).What is however even more important in my view is that the ceramic material in this knife has a grindability that is more or less comparable to S90V steel, something i discovered when resharpening the edge on my Tormek T7, which is fitted with a silicon carbide stone.

In only a few slow passes i had a completely new edge.

(as a comparison: S90V steel sharpens like annealed 420J2 when compared to a Kyocera ceramic knife on the same stone)Now from experience with other ceramic knives i've learned that the resulting edge needs refinement before being used (toothy edges are a no no on most ceramic knives), so that is what i did with the edge on this knife as well (with various diamond compounds), but in a later stage i plan to experiment with less refined edge types a bit to see how these hold up.

All in all more testing is needed to get a better understanding of how the current generation of ceramics in knives perform to have some benchmarks, as i think we will see much more improved types of ceramic in knives (and other articles) in the near future."